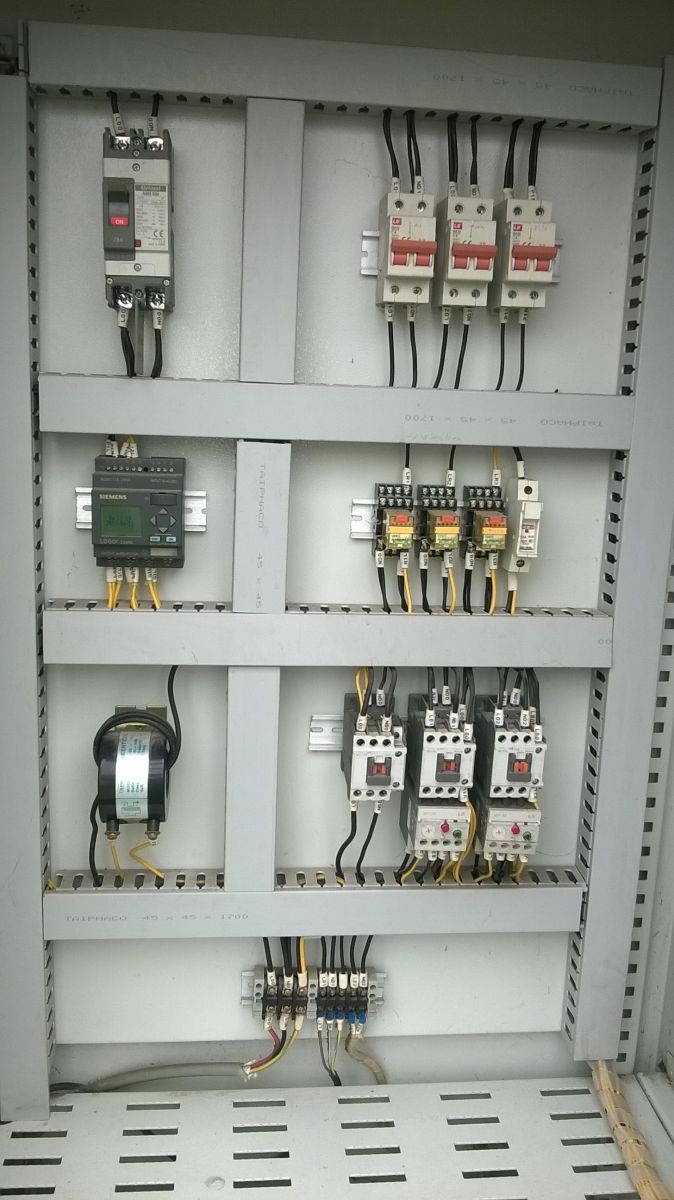

DOMESTIC WASTEWATER TREATMENT SYSTEM IN JCU PLANT

Figure 1. Wastewater treatment system in JCU Plant

| Maintenance Items | Periodic Maintenance (once in 3 months) |

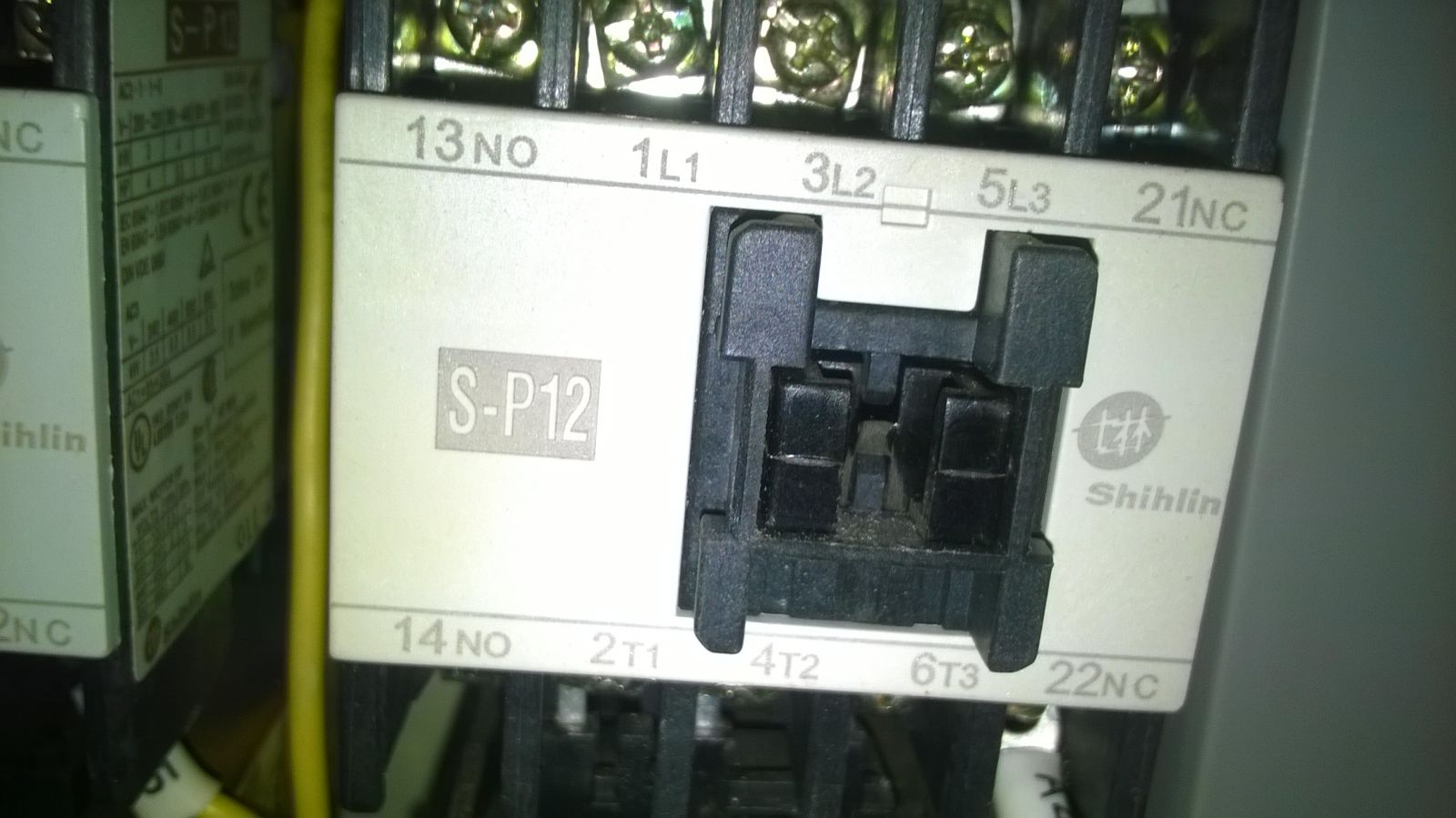

| Control Cabinet |

- Check functions of devices in electric cabinet - Check insulation capacity - Check electric current - Check parameters installed for PLC and program source code |

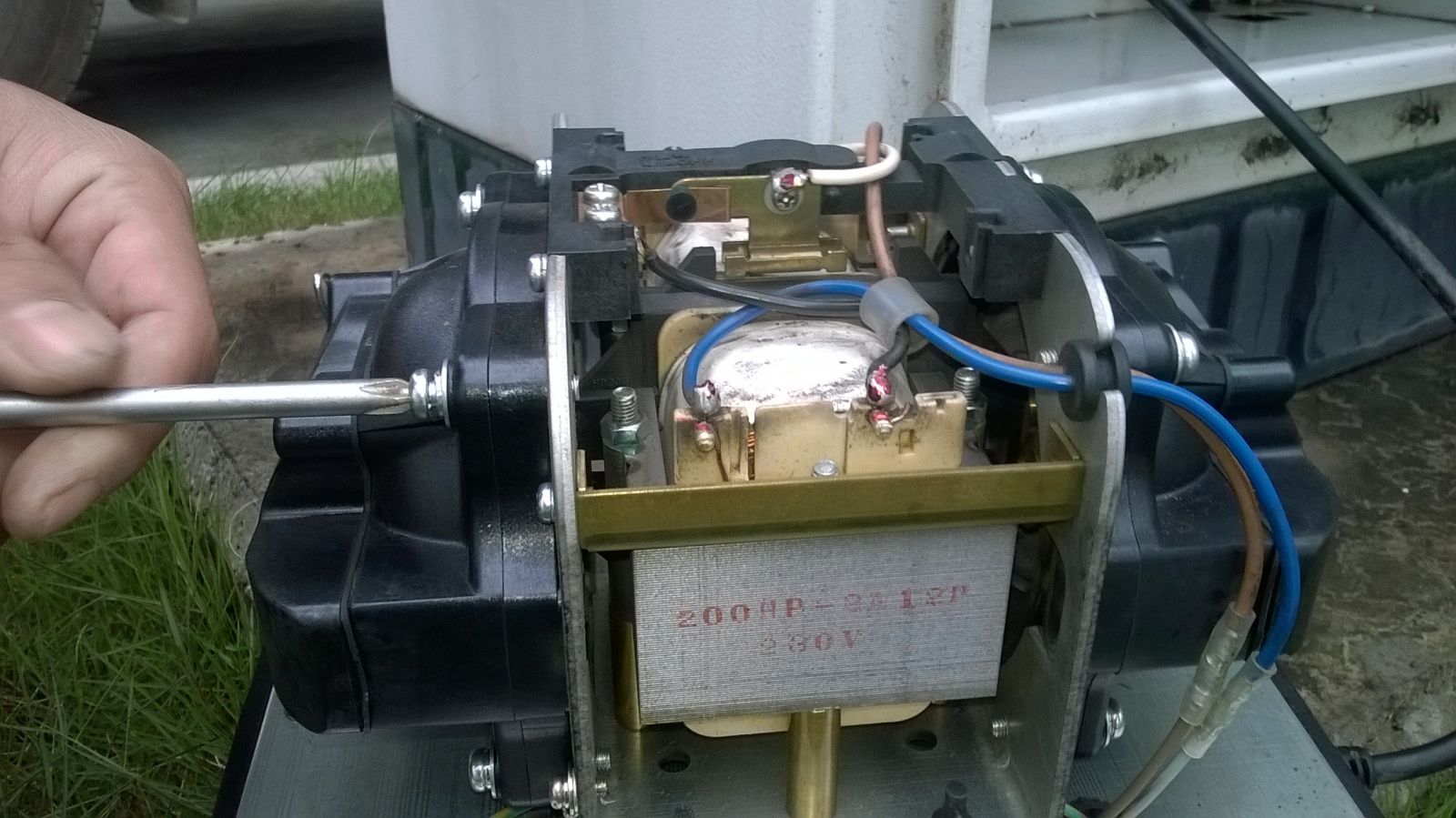

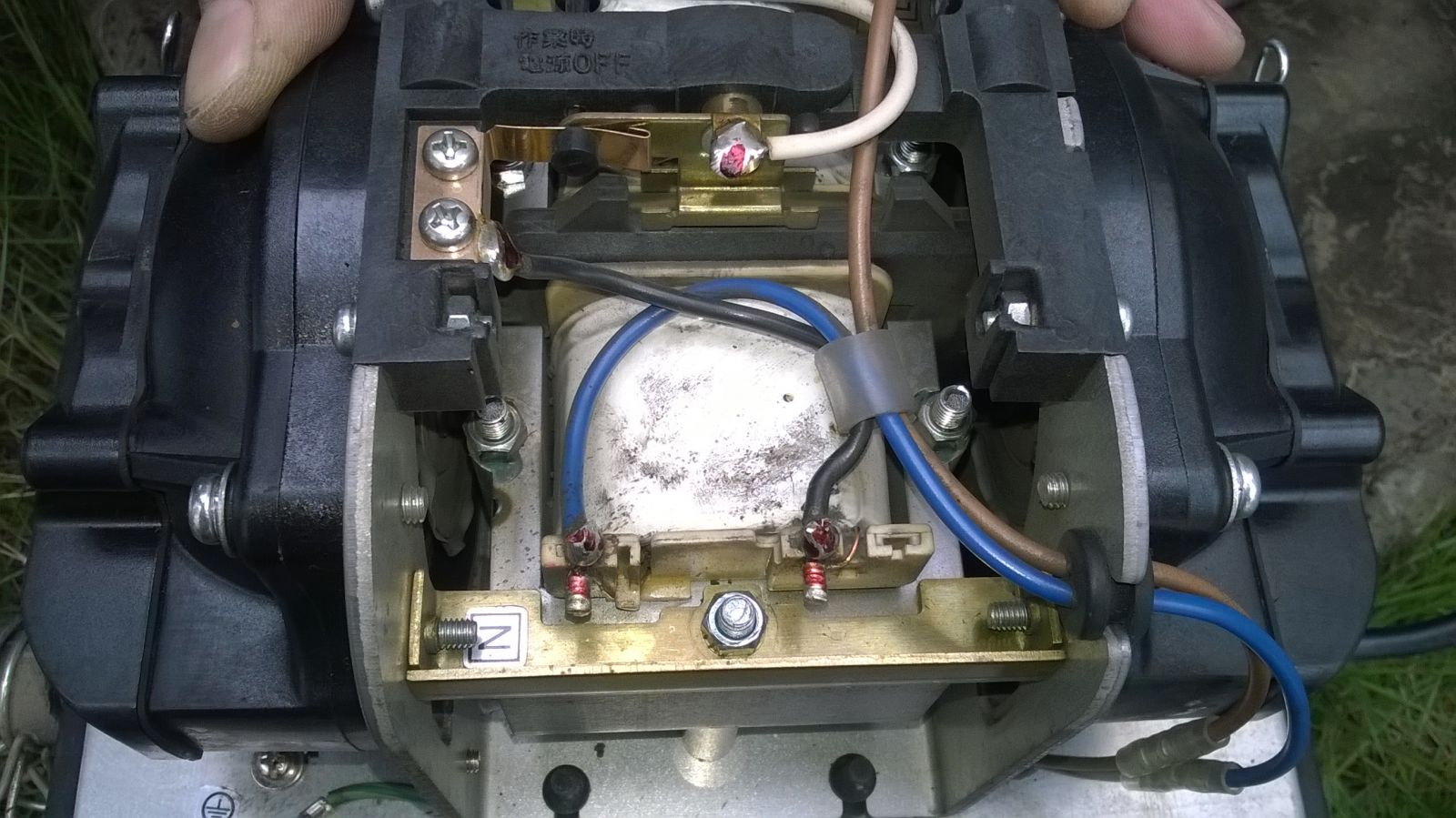

| Gas blower machine |

- Clean dust filter - Check electric current/voltage - Check the noise, viberation and temperature of machine - Check diphragm gas pump - Check and fix electrical leakage (if any) |

| Electromagnetic valve |

- Check functions - Check gas leak - Check electric current/voltage - Check and fix electrical leakage (if any) |

| Maintenance Item | Periodic maintenance (once in a year) |

| Tank Compartments | - Check and clean tank compartments |

| Control Cabinet |

- Disconnect CB, clean all inside and outside accessories (contactors, switch, etc.) with a dry brush. - Check all joints in electric cabinet. Squeeze the joints, take strange objects out and press the joints if necessary |

| Gas blower machine |

- Clean the ouside of machine and pump box - Replace the dust filter - Check and replace other broken accessories |

| Electromagnetic Valve and INOX pipe |

- Check the function of electromagnetic valve. - Clean the gas system, check valve’s function and replace accessories if necessary - Re-paint the whole gas system |

| Dredger Pump |

- Overhaul and replace leaked parts if necessary - Dredge sedimentation tank and anaerobic tank |

| Tank Compartment |

- Overhaul and replace parts if necessary - Clean waste seperation net and reactor net. - Clean the neck cap and tank cap |

Figure 2. Check the control cabinet of wastewater treatment system

- Quaterly, Fudeso will send staff to Plant to check, maintain and make a maintenance record of system operation, system problems, solutions and fees for fixing problems, etc. Fudeso has responsibility for making report of maintenance process for JCU.

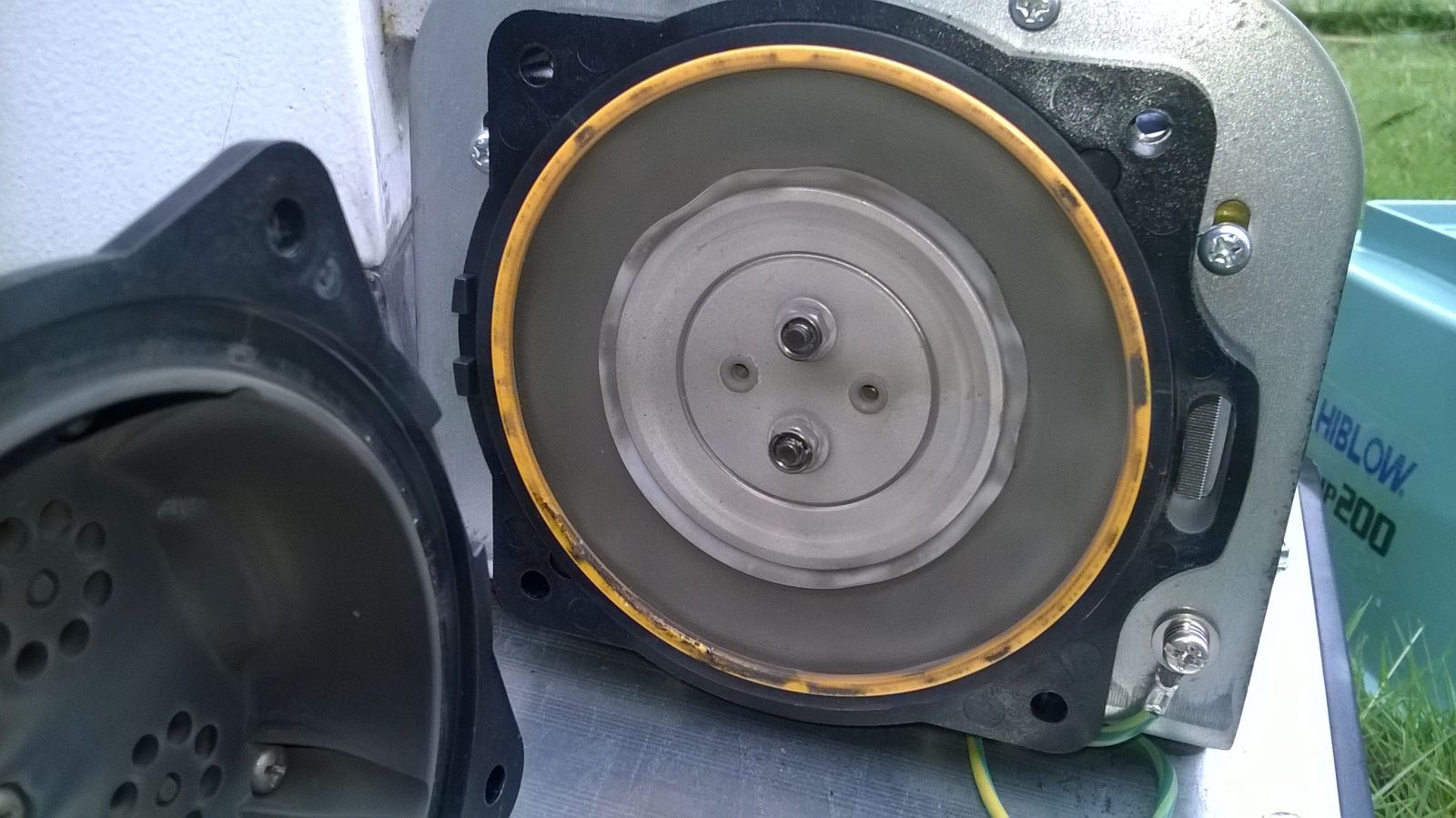

Figure 3. Clean and maintain gas blower machine

- If there is any problems in the system, Fudeso commits to present within 48 hours after receiving the requirement of assisstance from JCU and immediately fixes the problem when receiving an annoucement, preventing negative effects to production activities of the Company. The system operates well, ensuring the quality of output water.

Figure 4. Clean the diphragm of gas blower machine

- Fix, replace and repair broken devices or wastewater treatment system with problems. Fudeso will bear all costs of purchasing materials and devices if they need replacing or repairing during the warranty time in accordance with the Contract.

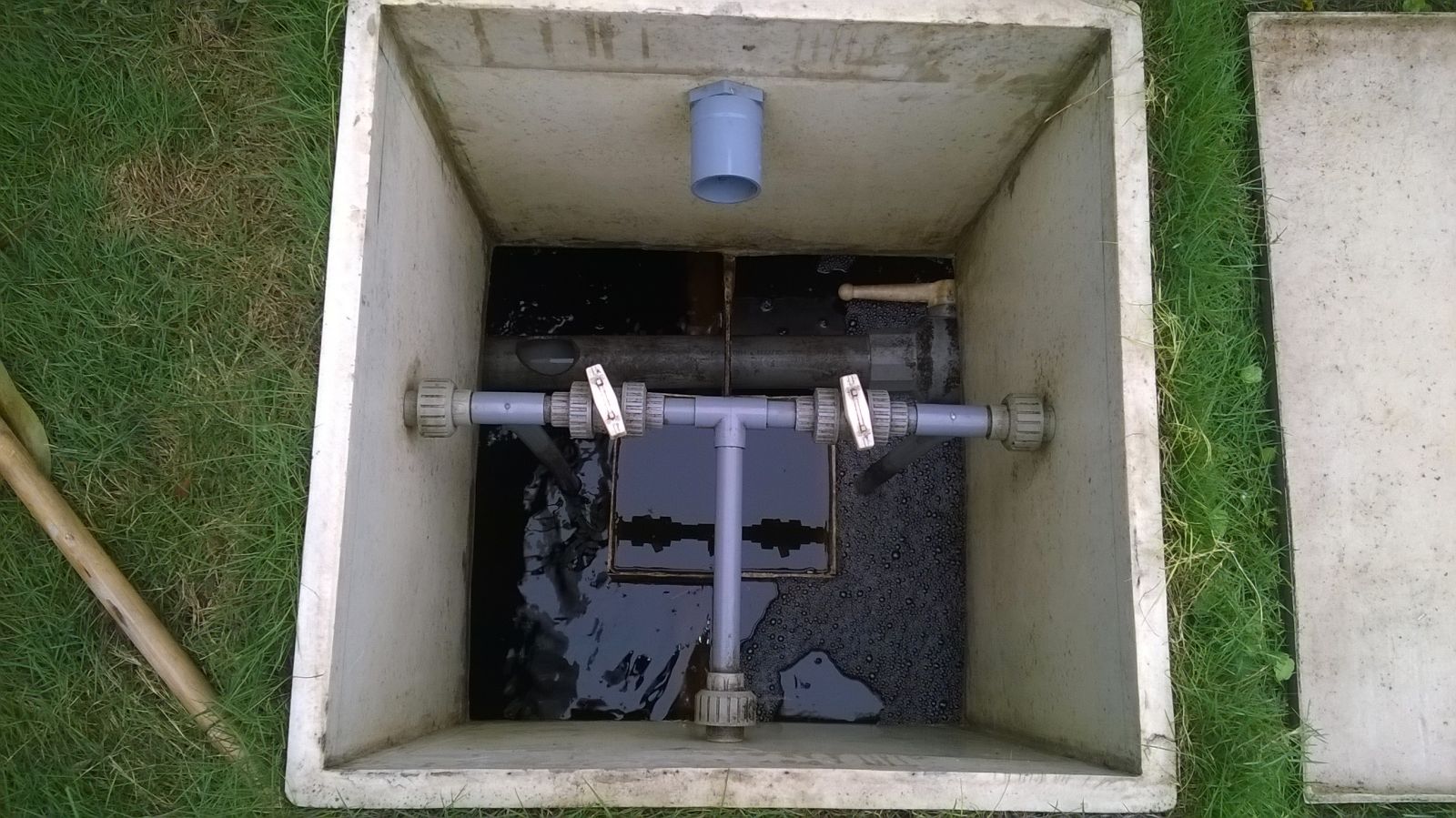

Figure 5. Clean tank cap and pipe

- Future Development Solution Joint Stock Company has 5-year experience in designing and constructing system of wastewater treatment for plants and enterprises. Especially, with dedicated and experienced staff who are always willing to learn as well as Johkasou technology transfer from Japan, we are always ready to meet all customer’s demands of wastewater treatment system and maintenance of wastewater treatment substation when it is operated.