Jokaso MBR

MBR process was studied in the late 1960s, when ultrafiltration membrane (UF) and microfiltration membrane (MF) were developed. The initial process was made by Dorr-Oliver Inc, where the MBR combined the use of an activated sludge biological treatment tank with a membrane filter ring of cross filter type. Film-forming materials are polymers, typical membrane hole size ranges from 0.003 to 0.01 μm. Although treatment efficiency of the membrane is highly valued, however, because of the high membrane production costs, MBR fabrication technology is simple, the membrane is often clogged and needs to be cleaned regularly, so the MBR is only little applied.

The breakthrough of MBR was made in 1989, by Yamamoto and his colleagues, by impregnating the membrane in biological treatment tanks. At that time, the MBR was designed with a membrane suction pump located outside the treatment tank and based on pressure on the membrane to maintain membrane filtration. Simultaneously with this improvement, air is supplied directly to the membrane, creating a mixing of activated sludge concentration, and minimizing the amount of sludge sticking to the membrane. These improvements make the biodegradation in the membrane better, the membrane is less congested, and also the life span of membrane is increased.

Jokaso MBR is an advanced wastewater treatment process, applicable to particular Jokaso installation locations. Jokaso MBR has outstanding advantages such as: small installation space, after-treatment water quality meets the strictest requirements of most waste discharge areas (after-treatment water quality is higher than Standard A - QCVN 14: 2008/BTNMT).

MBR technology (Membrane Bioreactor): is a biological wastewater treatment equipment incorporating the activated sludge (AS) technique activated with a filtration membrane with a very small membrane hole size of 0.1 - 0.4 µm. Thus, it can retain most of the sludge, organic and inorganic suspended dregs and also pathogenic microorganisms. High concentrations of activated sludge in MBR tanks can be up to 15 g/l (average

maintaining at 10 g/l).

This treatment technology has been very popular in the world since the 1990s, and has been applied in Vietnam for about the last 5 years.

.jpg)

Jokaso MBR made in Fudeso

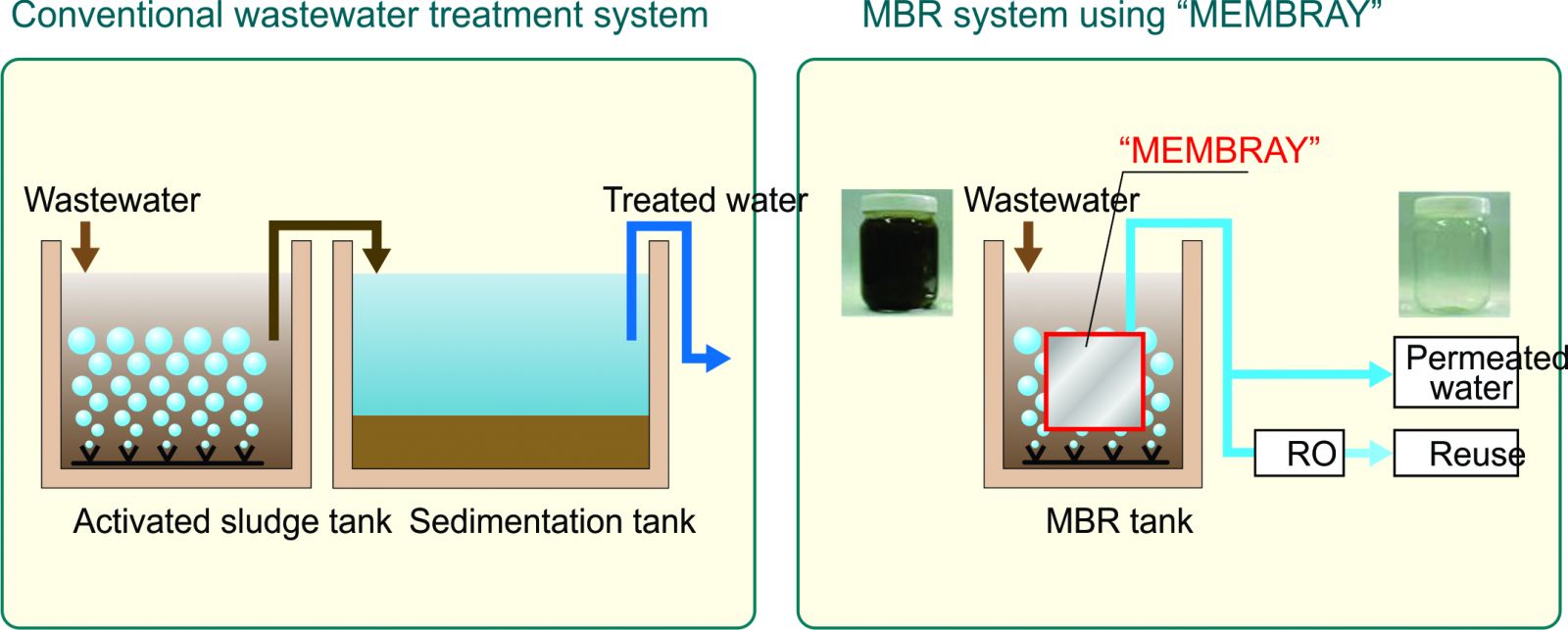

Jokaso MBR membrane treatment technology diagramph compared to traditional technology:

The essence of MBR technology is the process of wastewater treatment using a dynamic bio-tank system with operational process of SBR with aeration interruption and intermittent flow technology, combined with the dreg separation using a high molecular Nano filtration membrane, very small membrane hole size only for pure water to pass through, sludge and other impurities are retained so that the amount of sludge in the reaction tank is very large, can reach over 8000-15000 mg/l. (For normal activated sludge works, the sludge content is only 2000 - 3000 mg/l).

Membrane modular completely installed

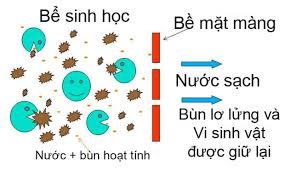

- Microorganisms, suspended solids and mud are completely retained at the membrane surface, the pure water is pumped out, the mud is retained in the tank and periodically drained to the sludge tank.

.jpg)

- As the hole size of MBR membrane is so small, the biological mud and microorganisms will be retained in the reaction tank, so that the high concentrations of microorganisms increase the treatment efficiency. Clean water is pumped into the storage tank and discharged into the environment without going through deposition tank, filtration and sterilization.

The superiority of Jokaso MBR technology

- The after-treatment water quality is higher than the quality in Type A of QCVN 14:2008/BTNMT. After-treatment water can be reused for many different purposes.

- Construction and installation spaces are saved the most compared to other technologies; It is not necessary to use secondary deposition tank, sterilization tank, in addition, the volume of sludge tank and reaction tank is smaller than the other microbial treatment technology.

- High automation.

- Usually installed in the form of block (Equipment or module form), so it is easy for the construction and installation as well as removal.

- In case of sudden changes, the system is adjusted for stability by no aeration - aeration - no aeration technique.

Currently, Fudeso is the distributor of MBR Toray membrane of Japan. The MBR Toray (Membray) has a 0.08-micron membrane hole size, helping eliminates molecules in above 0.1 microns, improving after-treatment water quality. Membray also has the unique hole size, the numbers of small holes are evenly distributed across the membrane surface with narrow distribution diameter. This structure ensures higher after-treatment water quality, increases the high permeability, decreases the obstruction. Membray in panel form, materials of PVDF (Polyvinylidene fluoride) for functional layers of membrane and PET (Polyester) as the membrane frame, make the membrane a stable structure. At the same time, Membray's structure in panel form allows high efficiency of membrane cleaning, thanks to the up-flowing water under the effect of cleaning air flow diffused below. This mechanism makes the membrane filtration process stable and does not allow the activated sludge to stick to the membrane surface. Combined MBR with RO filtration membrane can reuse water for living purposes, applied in scarce areas of clean water.

Please contact we Fudeso!

Fudeso strictly applying Jokaso standards from Japan has implemented the settlement of projects using MBR membrane processing systems (Mainly used Toray membrane) in the form of: Consulting technical design and detailed design; Supplying and installing the wastewater treatment systems; Guiding to operate and transfering technology. Ensuring the after-treatment water quality meeting the emission standards as committed.

After a one-year warranty, Fudeso continues to offer and renews the contract of product maintenance service package for the investors. Maintenance contract signing period is 1 year. See more about Fudeso's wastewater treatment system maintenance services here.

Hollow fiber MBR membrane

Flat sheet membrane of Toray Japan